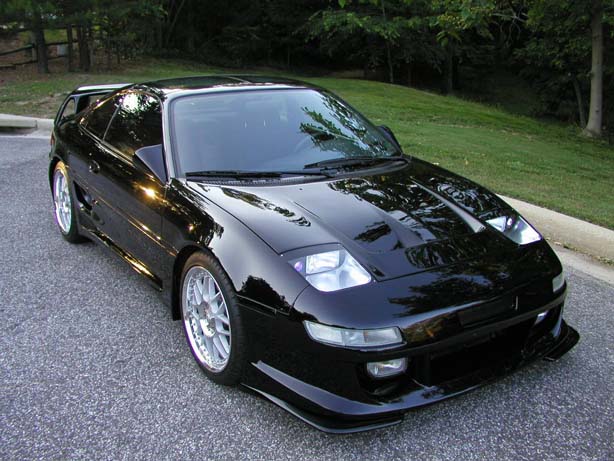

The Beast

Flush-Mount Headlights

Update 03-18-04 See Below

____________________________________________________________________

Prolog: 27 October 2002

Flush mounted lights are really cool. I love the way they look. They bring

back the classic style of the old Ferrari race cars. They are also more

aerodynamic than the pop up's.

I get hundreds of e-mails from guys begging me to make them a set or

asking for help in making their own. I have tried to put a lot of

information on the Beast site to help those who want to give it a try. The

problem is that most people don't have the shop skills or proper tools to

fabricate something that will work.

On the surface the lights look simple. The reality is that they are far

more complex.

I don't recommend doing the metal bases if you are good with fiberglass. The bases

that were used were custom

built using ideas from a number of previous projects and ideas picked up

from looking at different bases including Street weapon's design.

Although this set uses some of the features seen in other lights, they were

custom built by laying up fiberglass over polyurethane forms. The poly

urethane was then carved out, leaving the fiberglass bases. The bases were then

modified to accept the H4701 GE bulb and the small projector light at the

outside corners. I would estimate that I have $2400 in the current set.

Problem areas are this:

a. sealing the lights from moisture

b. finding a solution to having both bright and dim in a small bulb.

c. building the lights to a quality standard that will match the rest of

the car.

d. dealing with heat buildup inside the light housing

e. Making the compound curved lenses correctly

I have made a number of the lenses both from Polycarbonate and Lexan. I am

finding the Poly lenses easier to mold. The Lexan supplier will only sell

me 4' x 8' sheets. It's very expensive. It takes a special band saw and

blade to cut it or the edges melt.

I mold them in my oven at 215 degrees for about 15 min. One out of

three lenses will mold correctly. I usually manage to make enough to break even

when I sell a set for $150.

Now the bottom line. Most guys don't want to go through all of that. It's

a lot of work, trouble and money to end up disappointed with the end

result. As I have said before, the Beast is mainly a fair weather car and

practical lights are not as much of a requirement as your daily driver.

I hope this helps clear up a lot of the questions that you guys have.

___________________________________

Now back to the original text.

Consider the data below as historical information on the development of the

Flush Mounted light project. I have included it to assist you in

building the original aluminum based lights.

______________________________________________________________________________________________________________

Update March 18,

2004. After using the flush mounted lights for two years I have

finally made the change to bulbs which have both "bright" and "dim"

filaments in the same bulb. As you may recall, the original 4701

light bulbs were a high beam only unit. They were selected because

they were the only US DOT approved bulbs that would fit in the fiberglass

housing. They are 3" x 5.5" not including the border.

The solution was to carefully remove the old filaments and replace

them with dual filament, replaceable, bulbs made for other types of

headlights.

I found the bulbs at Walmart @ $18 for a pack for two.

They are GE 9004HO High Output Xenon with an average life of 700

hours. I cut off about 75% of the rear skirt on each bulb so they

would not stick out so far in the rear. The white soft protectors on

the old 4701 bulbs were removed, and that exposed a small Phillips screw.

Once that was removed the filament could be taken out leaving a square

hole. I used a carbide bit in a die grinder to open up the hole to 1 and

1/8th inch so that the new dual filament bulb would slide inside the old

glass. Black silicone calk sealed it up. New three prong,

female connectors were bought at NAPA auto parts, part number LS6493.

It says NAPA ECHLIN on the box. These were soldered to the three light

wires, High beam is Red/yellow, Low beam is Red/blue and the center

hot wire is Red/ green for the left light and Red/black for the right

light.

Understand, that the Toyota bright/dim switch is simply switching the

ground between the two filaments in the bulb, ie wires (Red/yellow and

Red/blue) to dim the lights.

___________________________________________________________________________________________________________________

Update: March 8, 2002. Big changes have been made to the flush mounted lights on the Beast. Recent changes in the front bumper and Border hood have required that I redesign the lights. I decided to build a custom fiberglass base for the lights that uses the Philips H4701 sealed beam and a single projector light. The sealed beam is one of the smallest US spec sealed beam available. The base was built so that the sealed beams install from the front. The new lights produce much better light than the older round units seen in the photos below.

My thanks to Dennis Lyons of Impatient Creations restoration shop in

Birmingham, AL for their assistance and help in the joint project to

develop the new lights.

Now, back to the story.

MR2 owners have long admired the aerodynamic look of flush mounted

lights on the Ferrari F-40 and other exotics. Their smooth, low drag

design would be a functional addition to the second generation MR2. Many

Mk 2 owners have dreamed of adapting similar lights to their own machine.

The few Mk2's that are seen in magazines sporting the flush mounted lights

are usually "one off" designs created by their owners. The

addition of FMHL to the Beast has been an idea that finally worked its

way into reality. " The first time I saw a MK2 I thought how cool

they would look on the car. Toyota missed an opportunity by not designing

it that way". The new lights are lighter, simpler, have less drag,

work as well or better as stock, allow you a choice of individual light

units, and generally look better than the old pop up lights.

____________________________

The Aluminum Base Lights

Information on the original aluminum light set. This

information is you those of you who want to build the original design,

aluminum base lights.

The prototype set was made by making an aluminum box traced from a

pattern, cutting several 4" holes in the rear of the old head light

area, wiring up the lights and installing the pre formed Lexan clear

covers. A "Beta Test" version has already been sent to someone

on the IMOC list who will build it and assist in working out the bugs in

the system. One of the most difficult parts is bending the aluminum boxes.

It can be done with a regular metal brake (bender) but a box brake with

removable sections works much better. The other difficult part is forming

the clear Lexan covers. They have to be done carefully in order to keep

the optical clarity and proper shape. "Having good shop skills, a

place to work and better than average tools is a must before someone

begins this project," says Jim. "This is not a Saturday

afternoon, shade tree job. If your car is your daily driver, you need to

build the boxes first, have all the parts and tools ready, and do one

light at a time. Taking your time and doing good work is

important."

Finding someone with a Box Break metal bender will speed things up and

make a nice job of bending the aluminum. Without it, you will make a

mess. It does require removing some metal behind the old lights that

you remove. I left enough behind so that I could replace my original

lights in the future if I changed my mind.

The actual bulbs can be any 4" round lights you can find. Mine

are halogen, "Blazer" lights from Walmart. They work fine,

but I plan to replace them with stronger HID units in the future.

Condensation: Depending on where you live, you might have some

condensation problems inside the lenses. I drive mine here in the

South and see very little of it. I bought two tiny 12v computer fans

from Radio Shack and plan to install one on the bottom side of the base on

each unit, to pull air through the enclosure.

The stock bright dim switch is used to switch the ground between relays

that cut the power to the outside lights on dim. The inside lights

have more down angle than the outside lights for dim. The lights are

sealed in place with silicone calk that remains somewhat flexible and

allows a cable tie to be used to adjust the up or down angle. This

system of adjustment was simple and worked well.

__________________________________________

How to make the lenses

Remove the old headlight tops to use as a mold. I bought white felt at a fabric shop and stretched it across the tops of the old headlight covers to keep the Polycarbonate or Lexan from sticking. My latest lights use Polycarbonate lenses in 3/16th thickness. I found them easier and cheaper to mold. So far they have held up very well.

I had to use thin wire under the back side to hold the fabric tight (like lacing it up). I set the oven at about 215 degrees F and let it warm up. Cut the lenses to correct size and shape (use a poster paper pattern) and put it on top of the cover. If you watch the plastic through the oven door, you can see them begin to sag down on the top of the felt. When they sag a lot, pull them out and press down on top of the Polycarbonate or Lexan with towels to finish forming them to the proper shape. Let it cool. You might have to do several to get it right. Good luck!

_______________________________________________

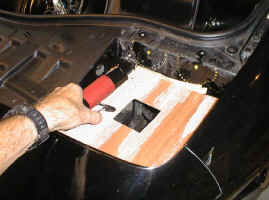

Photos of the building Process

Marking holes for lights. Metal must be removed from rear of

headlight area to allow lights to fit.

Wooden base support used in positioning aluminum bases during

fitting process. Hand operated, air saw (Sears or Lowe's hardware) is used

to remove metal.

Trial fitting lights with poster paper patterns

Fitting individual lights. Lights are held in place using

black silicone calk around the back side of the enclosure.

Light boxes are made of 40 thousandths aluminum and secured to the

inside of the car with metal screws

Color test in Black was rejected in favor of silver

Painted borders (inside surface) of Lexan lens.

The finished product

Feb, 2002 update: The original round flush lights were removed

and sold. The new set seen

in the top photo were a joint project between Impatient Creations body

restoration shop and myself.

____________________________________

The Fiberglass Base Lights

History: The aluminum lights were adequate but

were not as bright as needed. The bases were made from hand forming

aluminum sheet in a metal brake. This was not an exact science and

although the lights looked good, they lacked the quality of the rest of

the car.

A decision was made to look for a better design. There were several fiberglass designs on the market in Japan and one here in the US. After looking at the options it was decided to take the best features of the three sets and combine them into a single unit that would hold a US DOT approved sealed beam bulb. The GE H4701 bulb was selected along with a small projector lamp. Both bulbs can be found at Autozone and are inexpensive. The H4701 is a high beam unit used on 1988-89 GMC trucks and some cars. It was paired with the H4703 low beam to make up the set in the truck. The projector lamp is a 55 watt light sold for under $45 a set.

Polyurethane foam blocks were bought at an AC shop and carved into the shape needed to fit the openings. The mounting system used on the Street weapon lights were found to be the best and this design was used on the new set. Fiberglass was laid up over the forms and coated with resin. After hardening, the poly urethane forms were removed and the new bases, trimmed and primed. Further modifications were made to the bases to fit the projector lights beside the main bulb units.

Impatient creations assisted with the finishing of the

light units, final mounting of the bulbs and painting the silver

reflective coating. I molded several new sets of lenses from both

poly carbonate and Lexan. Several hours were spent fitting the

lenses to the opening formed by the Border hood and the new Phoenix front

bumper. I used a belt sander to carefully sand away the edges until

a near perfect fit is made. Once the lenses fit the opening, four

mounting screw holes are drilled through the lenses and into the light

bases. I carefully counter sink each hole in the lenses and use

counter sunk wood screws to mount the them.

The lenses are now ready for painting the black borders. I use a

high quality semi-gloss paint (spray can) on the inside of the lens.

The border is taped off using 1/4 inch blue painters tape, followed by

masking tape and paper to cover the remainder of the inside. Several

light coats are needed.

Wiring work requires that you have the Toyota factory electrical manual. You have to understand how Toyota uses the bright/Dim switch to switch the ground from the bright side connection to the Dim side connection. When you have the wires identified, you can experiment with a test light to be sure it works. I use a 1 watt wire wound resistor from Radio Shack to reduce the voltage on the Dim side. This is a temporary solution until I have the dim lights installed in the front of the clear corner positions. I plan to use an even smaller sealed beam found on late model Camaro for the dim lights.

Photos of the newest light design

The Beast Web ///|||\\\ Copyright ©

2000 Jim Griffin. All rights reserved.

E-mail: Ace123Jim@aol.com Web site:

http://www.MR2Beast.com

Last revised October 22, 2002.